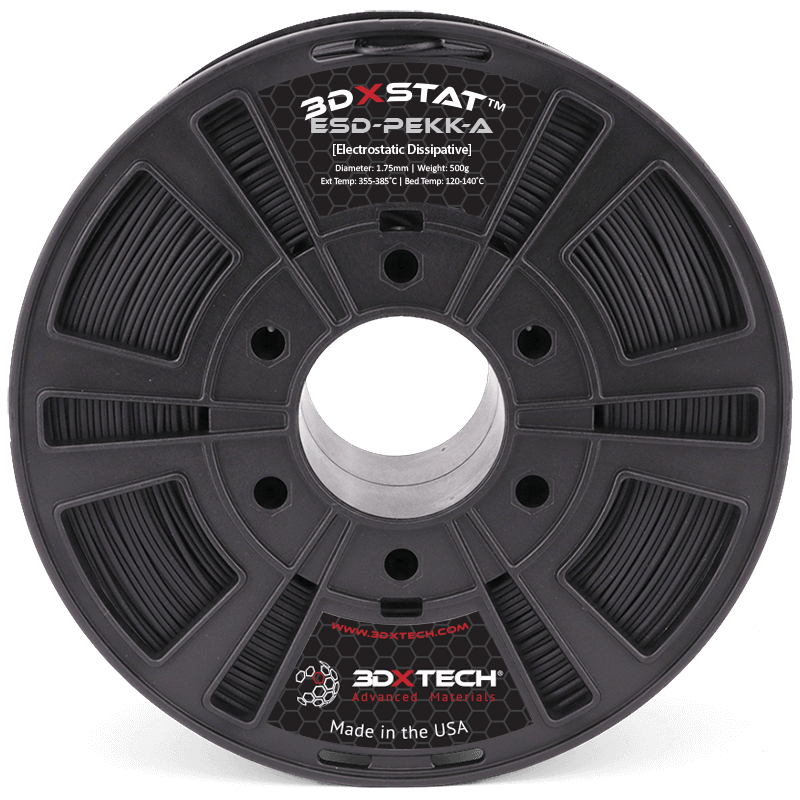

3DXSTAT ESD-PEKK-A

Made using Arkema Kepstan PEKK (PolyEtherKetoneKetone) and state of the art conductive additives, this ESD PEKK-A is one of the highest-performance polymers in world and ideal for demanding applications. This filament was created for the highest-spec situations where tightly controlled static dissipation, thermal properties, and mechanical performance properties are required. Target surface resistance of 10^4 to 10^9 Ohm.

MADE IN THE USA

We manufacture all of our filaments in our 68,000 ft² manufacturing facility (located in Grand Rapids, Michigan) using state-of-the-art equipment and processes. Our goal continues to be to make the most innovative filaments on the market – targeting difficult end-use applications.

Print Recommendations