Bio/Recycled Filaments

Bio-based and recycled 3D printing materials from 3DXTECH offer sustainable solutions across industries, reducing waste and reliance on virgin plastics while meeting performance standards. From aerospace to automotive and hobbyists, these materials support eco-friendly practices and drive operational efficiency.

Benefits of Bio/Recycled Filament

Bio/recycled filament is used in 3D printing to create objects that support environmental sustainability by reducing the reliance on virgin plastics and minimizing waste. These materials contribute to eco-friendly manufacturing practices and align with green initiatives, making them essential in industries aiming to lower their environmental impact while still meeting performance requirements.

Performance Driven Sustainability

Achieve the reliable performance you've come to expect from 3DXTECH, all while maintaining eco-conscious practices.

Reduced Impact on the Environment

Overall, the use of bio/recycled filament reduces the reliance on virgin plastics, helps reduce waste, lowers emissions, and promotes resource conservation.

Meet Environmental Standards

Ensure your projects align with growing environmental regulations and sustainability goals. Drive eco-friendly innovation in traditionally resource-intensive fields.

Versatility in Applications

Bio/recycled filaments have found a home in a broad range of end use cases, from manufacturing to electronics and even hobbyist projects.

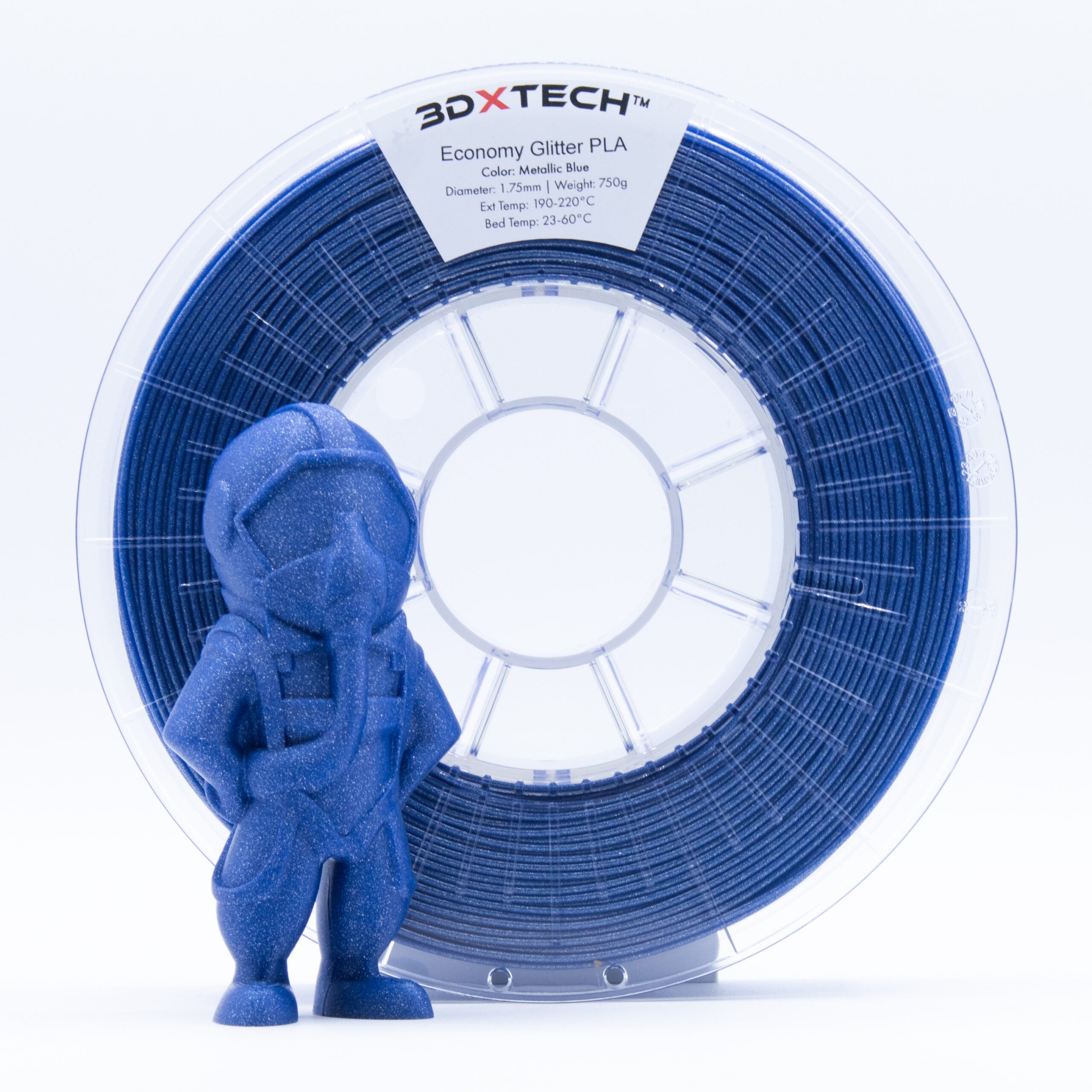

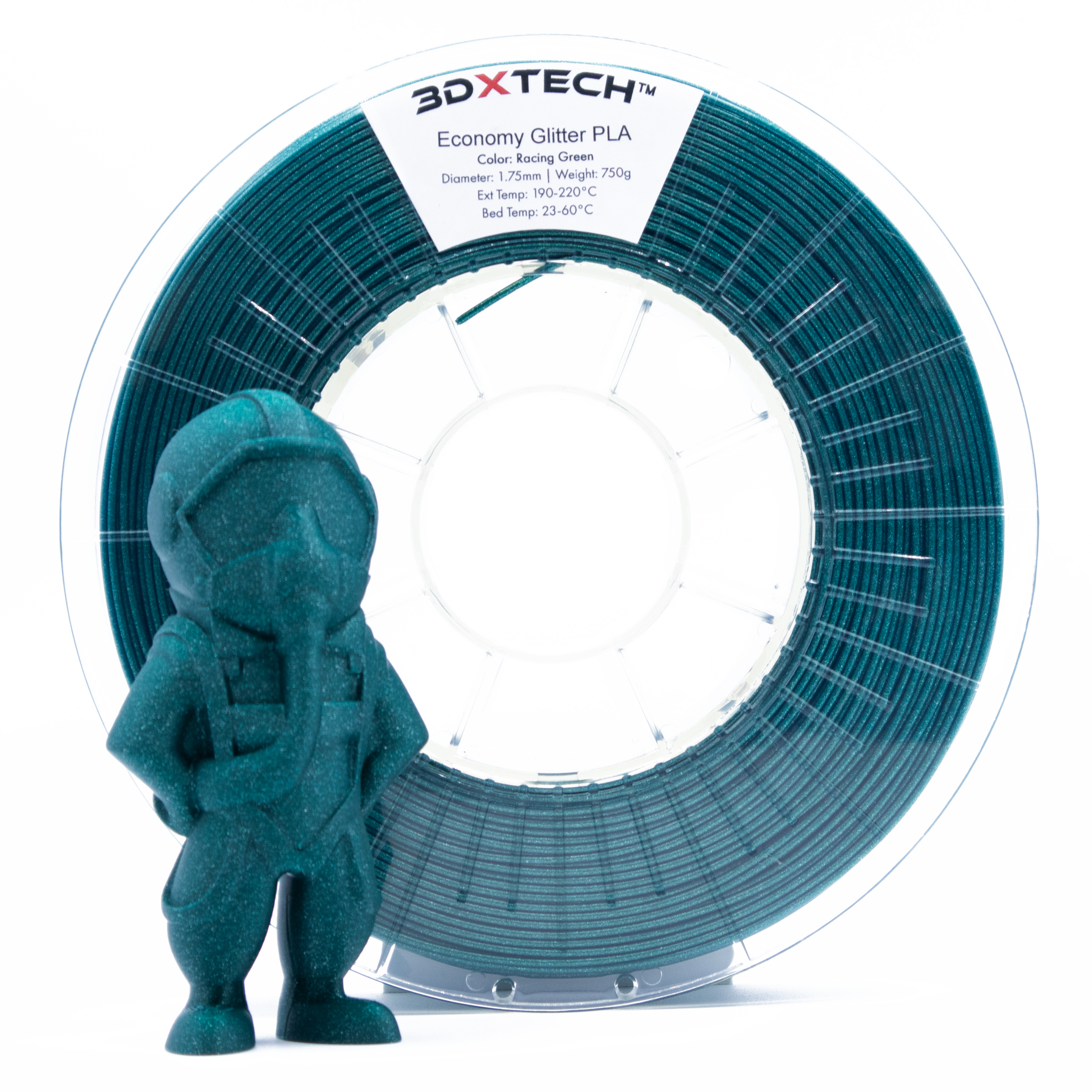

Shop Bio/Recycled Filament

We offer a large selection of bio-based and recycled 3D printing filaments. Our products are crafted from renewable biopolymers and high-quality recycled materials, using advanced compounding and precision extrusion technologies. These eco-friendly filaments deliver exceptional performance while supporting sustainability initiatives across various industries.

Applications

Bio/recycled materials are essential across industries for promoting sustainability, reducing waste, and aligning with environmental standards. In sectors like aerospace, defense, and automotive, these materials support eco-friendly practices without sacrificing performance. They help lower the environmental footprint in high-impact industries like oil and gas and contribute to the responsible production of electronics and medical devices, all while enabling hobbyists to create more sustainably.

Prototyping

Prototyping parts and tools, which helps reduce environmental impact during an iterative design process.

Custom Fixtures

Sustainable custom fixtures and tooling for production processes, helping to support green manufacturing practices.

Non-Critical Components

Production of non-critical or interior aerospace parts using bio-based or recycled filaments to support sustainability goals without compromising safety.

Aerospace Prototypes

Development and testing of prototypes for aerospace components, reducing the environmental footprint of the design process.

Training Equipment

Sustainable training aids and equipment used in non-combat scenarios.

Support Structures

Recycled or bio-based materials for non-essential support structures and components that help to align with sustainability initiatives.

Enclosures

Eco-friendly enclosures for electronic devices and accessories, providing necessary protection while minimizing the use of virgin plastics.

Cable Management

Sustainable cable management solutions such as trays and holders, supporting green practices in electronics manufacturing.

Interior Parts

Automotive interior components such as trim pieces, dashboard elements, and console housings.

Automotive Prototyping

Development of prototypes for automotive parts using sustainable materials, aiding in design validation while supporting environmental goals.

Protective Covers

Sustainable covers and protective elements for equipment that do not compromise on performance but contribute to reduced waste.

Non-Critical Parts

Use of bio-based or recycled filaments for non-critical components and tools that support the oil and gas industry’s efforts to incorporate more sustainable practices.

Medical Prototypes

Development of prototypes for medical devices and equipment using bio-based or recycled filaments, helping to advance medical technology in a more sustainable manner.

Custom Medical Tools

Non-critical or low-contact medical tools and accessories made from sustainable materials, supporting greener practices in healthcare.

DIY Projects

Use of recycled or bio-based filaments for hobbyist projects, including custom parts and models, allowing hobbyists to reduce their environmental impact.

Personal Projects

Sustainable prototyping for personal or experimental projects, providing a way to create functional items while adhering to eco-friendly practices.