Glass Fiber Filament

Benefits of Glass Fiber Filament

Glass fiber 3D printing materials offer enhanced strength, durability, and resistance to harsh conditions, making them ideal for industries like manufacturing, defense, and oil and gas. They provide a cost-effective, lightweight alternative to carbon fiber.

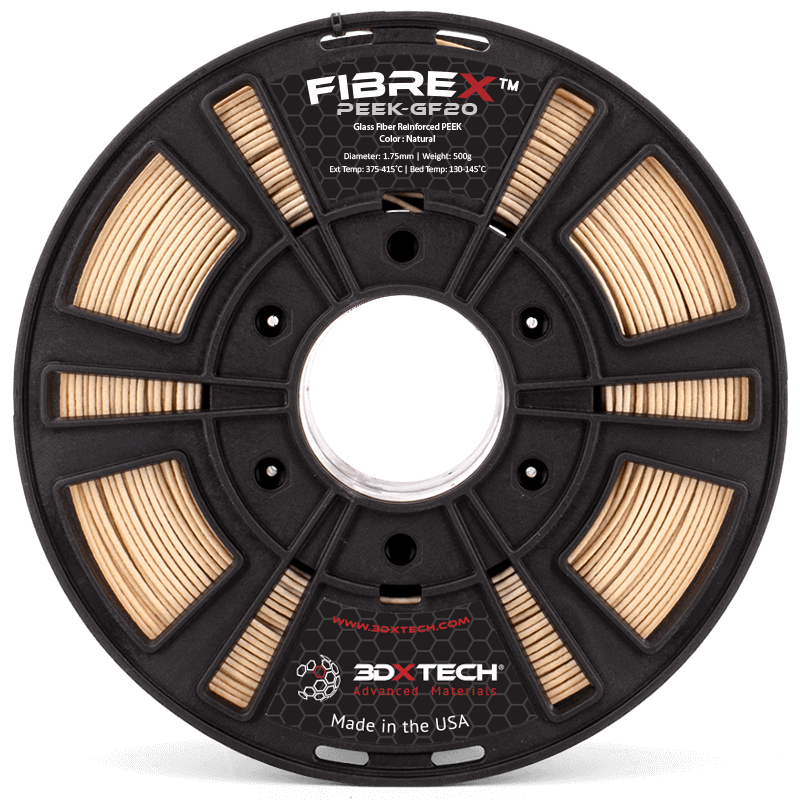

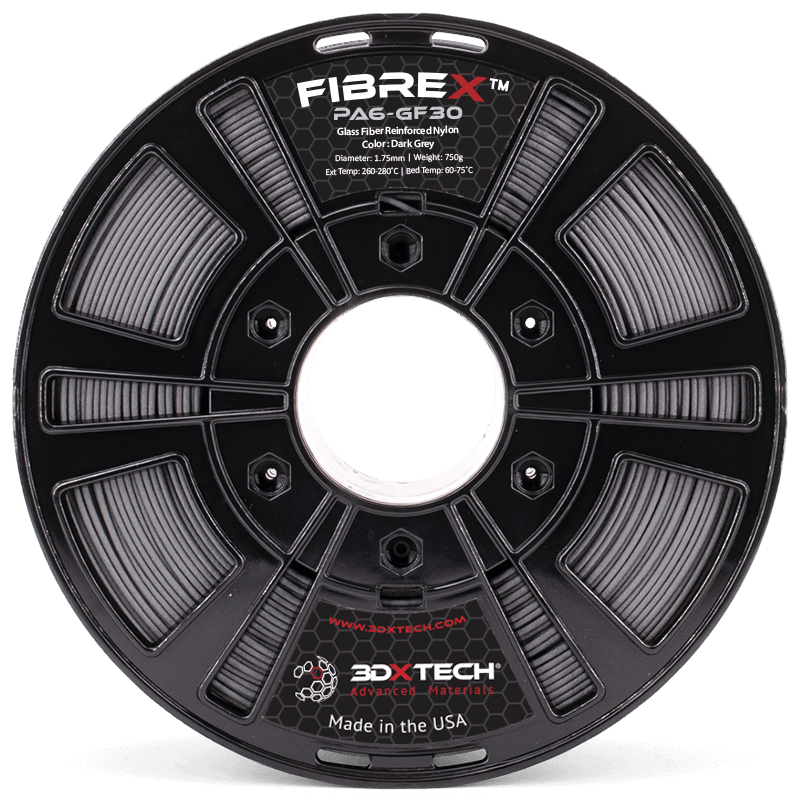

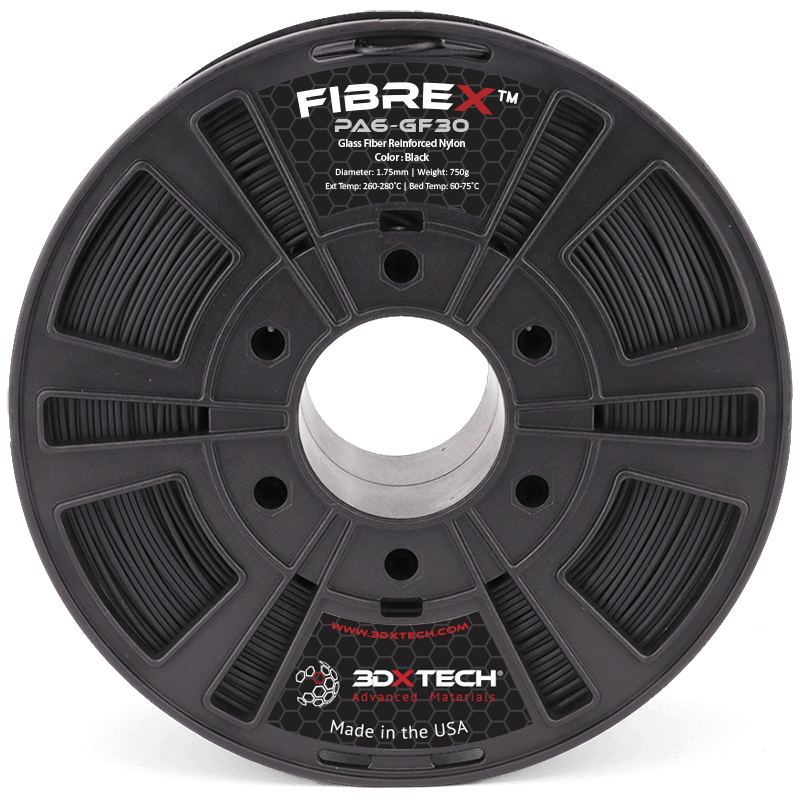

Shop Glass Fiber Filament

Applications

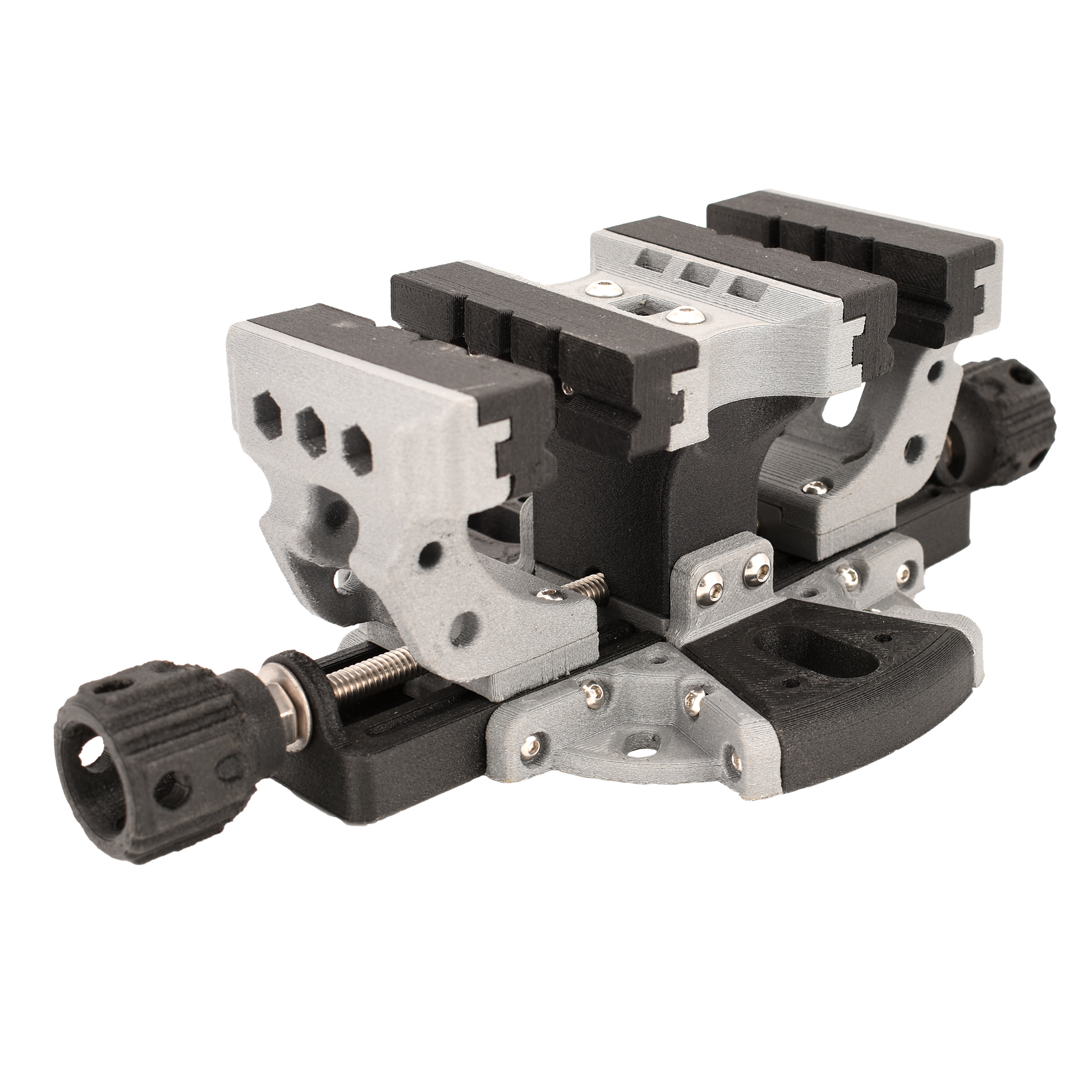

Tooling and Fixtures

End-Use Parts

Structural Components

Aerospace Prototyping

Durable Equipment Parts

Protective Casings

Enclosures

Mounting Brackets

Performance Parts

Automotive Parts Prototyping

Durable Components for Oil and Gas Companies

Protective Parts

Custom Medical Tools

Prosthetics

DIY Projects

Prototyping for Hobbyists

Why choose Glass Fiber over Carbon Fiber?

Choosing glass fiber over carbon fiber for 3D printing depends on several factors specific to each market's needs and constraints. Here’s why some markets might opt for glass fiber filaments instead of carbon fiber:

Glass fiber has excellent impact resistance and toughness, which can be advantageous in applications where parts are subjected to high stress or potential impacts. This makes glass fiber a good choice for rugged or heavy-duty components.

Glass fiber materials can offer good thermal stability, which is valuable in applications involving exposure to elevated temperatures. This can be crucial for components used in high-temperature environments or requiring thermal resistance.

Carbon fiber filaments are highly abrasive and can cause significant wear on 3D printer nozzles and other parts. Glass fiber filaments, while still somewhat abrasive, generally cause less wear and tear on printing equipment, leading to lower maintenance costs.

For some applications, the flexibility and impact resistance of glass fiber are more beneficial than the rigidity of carbon fiber. This makes glass fiber suitable for parts that need to absorb impacts or endure mechanical stress without cracking.

Glass fiber is often seen as a more environmentally friendly option due to its lower production costs and less intensive manufacturing process compared to carbon fiber.