3D Printing Prototypes and Models

Effective Rapid Prototyping

Using additive manufacturing for prototyping not only accelerates the design process but also enhances creativity and functionality, making it an invaluable tool in product development.

Rapid Prototyping

Additive manufacturing allows for quick turnaround times, enabling designers to produce and test prototypes in a matter of hours or days, rather than weeks.

Design Flexibility

Additive manufacturing can create intricate designs and complex shapes that would be difficult or impossible to achieve with traditional manufacturing.

Cost Efficiency

There's no need for expensive molds or tooling, making it more economical for small runs or one-off prototypes.

Popular Applications of Prototyping and Modeling

Rapid Prototyping

Prosthetics

Bone Modeling

Precision Modeling

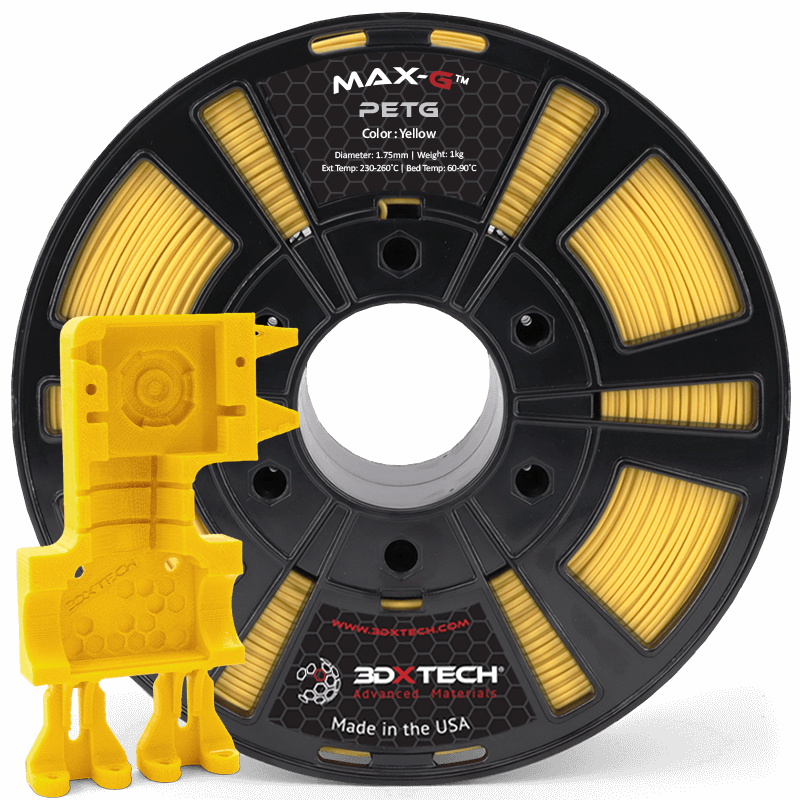

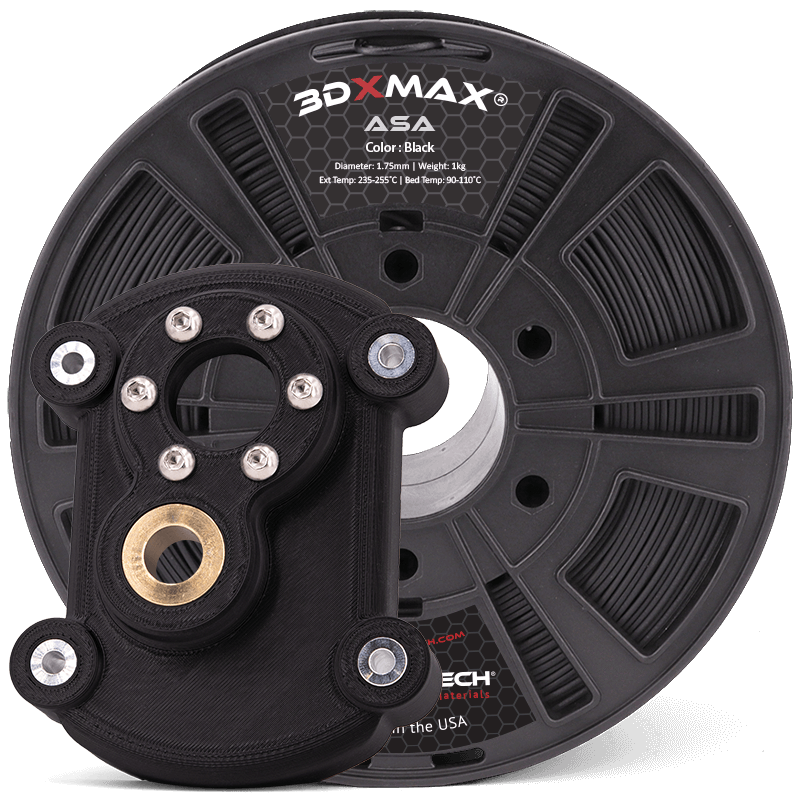

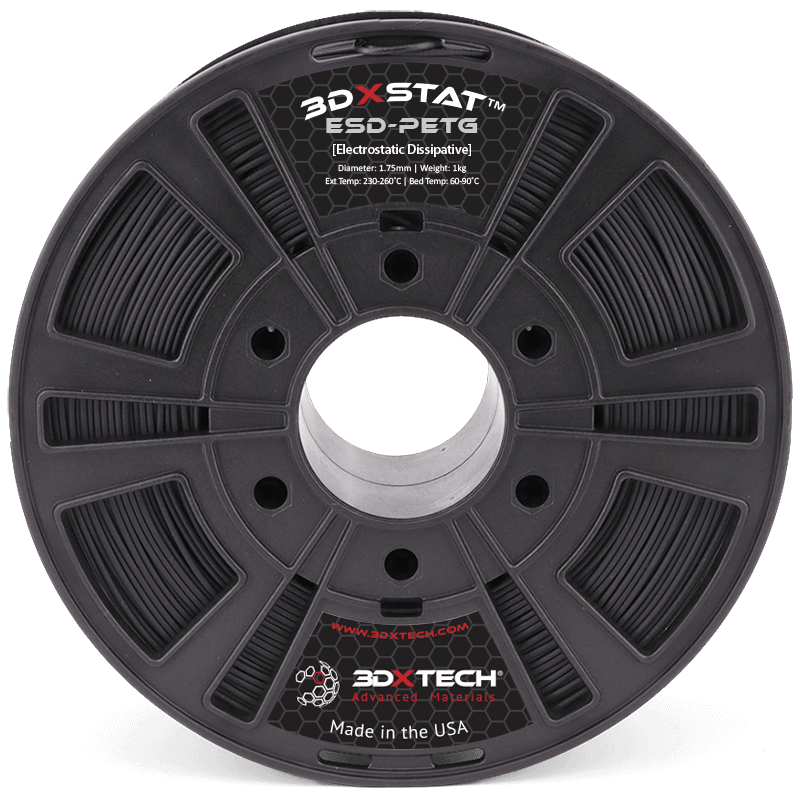

Popular Filaments used for Prototyping and Modeling

NEED STRATASYS COMPATIBLE FILAMENT?

Don't worry! We've got you covered.