Description

Ceramic-filled PEKK and PEEK compounds have a long history in the plastics industry – especially in the semiconductor industry where these materials have been used to machine integrated circuit (IC) test sockets and fixtures. CeramiX™ PEKK contains 15% (wt %) of high purity Alumina (Al203) which creates a hard surface ideal for repeated uses in electronics assembly and fabrication facilities. Please Note: This material was NOT formulated for applications that would create printed ‘green’ parts that would later be de-bound and sintered, leaving the ceramic additive in place.

Benefits of CeramiX PEKK

- Ease of printing

- High stiffness and strength

- Low thermal expansion below 150°C

- Easily machinable post-printing

- Excellent thermal properties (high Tg, HDT, Tm)

- Low moisture absorption

- Hard surface (100 Rockwell M)

Reviews

Print Recommendations

Extruder Temp

360-390°C

Bed Temp

120-140°C

Heated Chamber

Recommended Up to 140°C if possible

Nozzle Specs

0.4mm diameter minimum

Layer Height

0.25mm or higher

Drying Specs

120°C for 4+ hours as needed

Material DETAILS

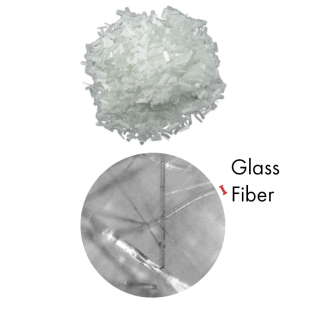

Glass Fiber Reinforced Filament

What Is It?

DescriptionFibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament.

This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

High strength

High stiffness

High chemical resistance

Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament which exhibits the best properties of both fiberglass and the plastic of choice.

What Is It Good For?

Ideal for any applications which require strength and rigidity.

For these reasons, glass fiber reinforced filament is very popular in automotive, mechanical, civil engineering, and research industries.

RECOMMENDED

You May Also Like

Make confident choices and discover the best printing solutions.