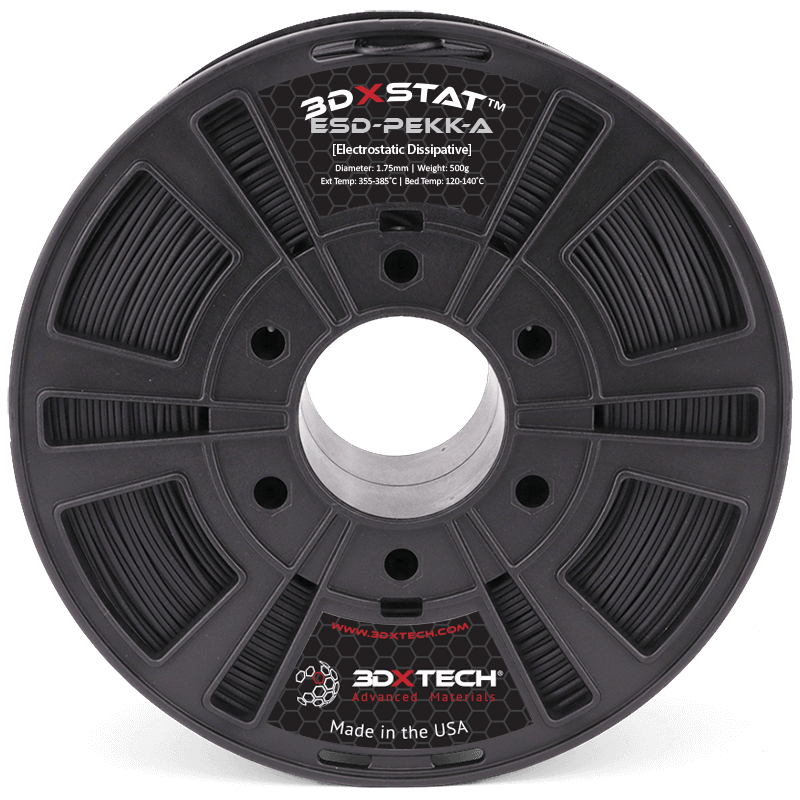

ESD-Safe Filament

Electrostatic discharge-safe (ESD-safe) materials are critical in manufacturing environments for protecting sensitive electronics, maintaining industry compliance, and ensuring reliable performance across high-tech production lines.

Shop Now

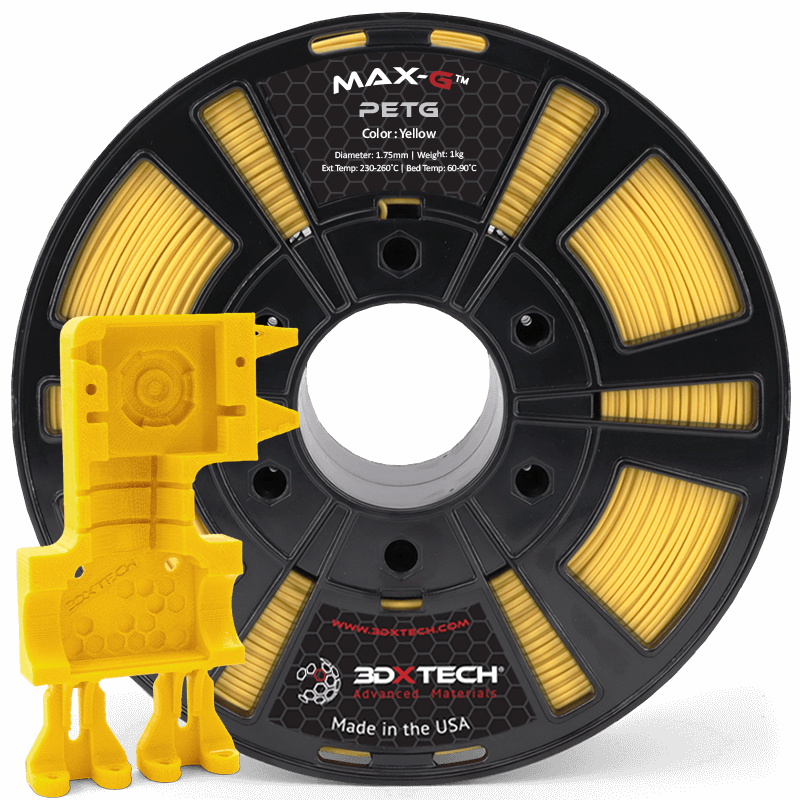

Glass Fiber Filaments

Glass fiber 3D printing materials offer enhanced strength, durability, and resistance to harsh conditions, making them well-suited for demanding manufacturing environments. They are ideal for producing strong, lightweight parts and tooling across industries like defense and oil and gas, while providing a cost-effective alternative to carbon fiber.

Shop Now

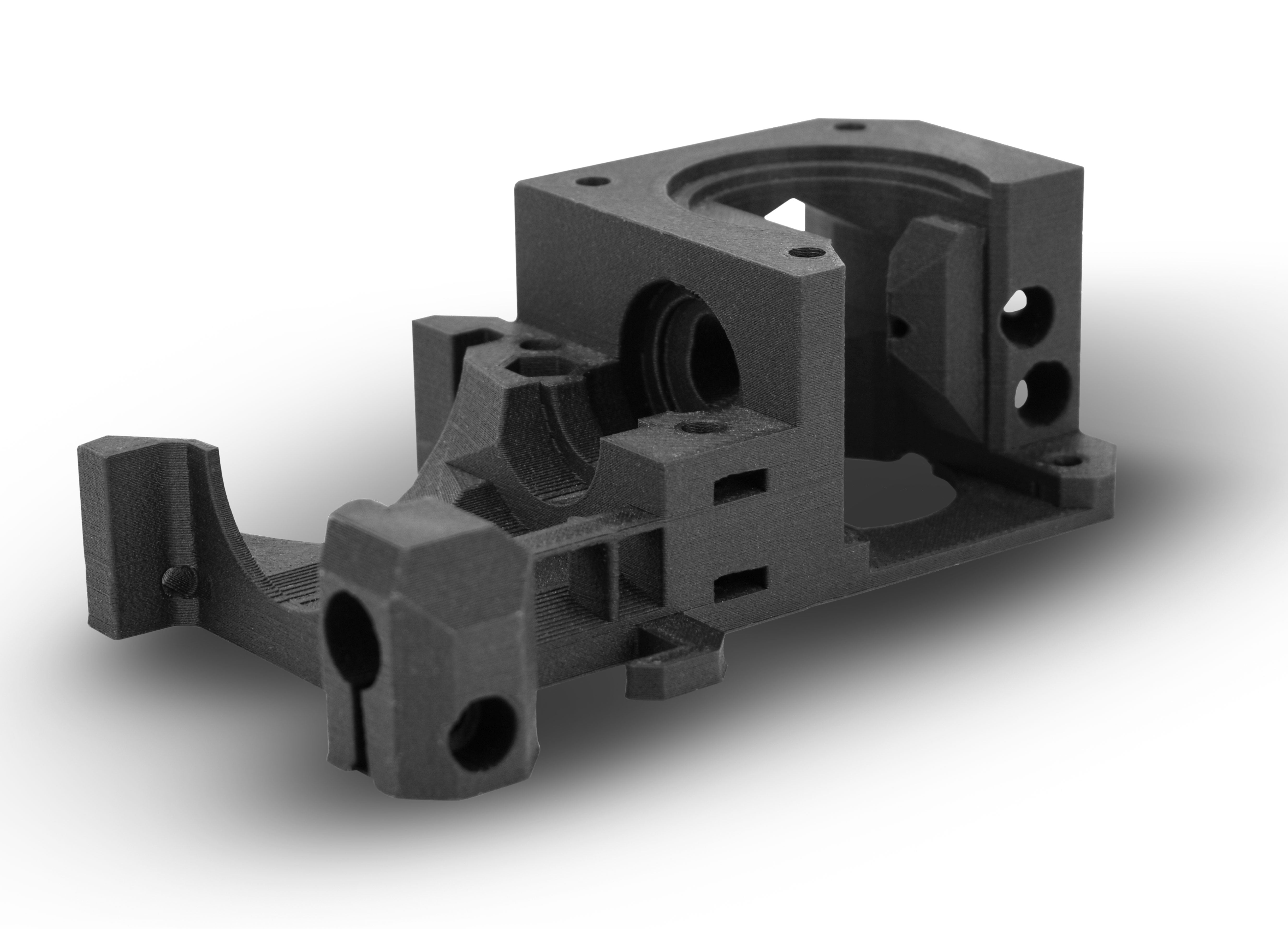

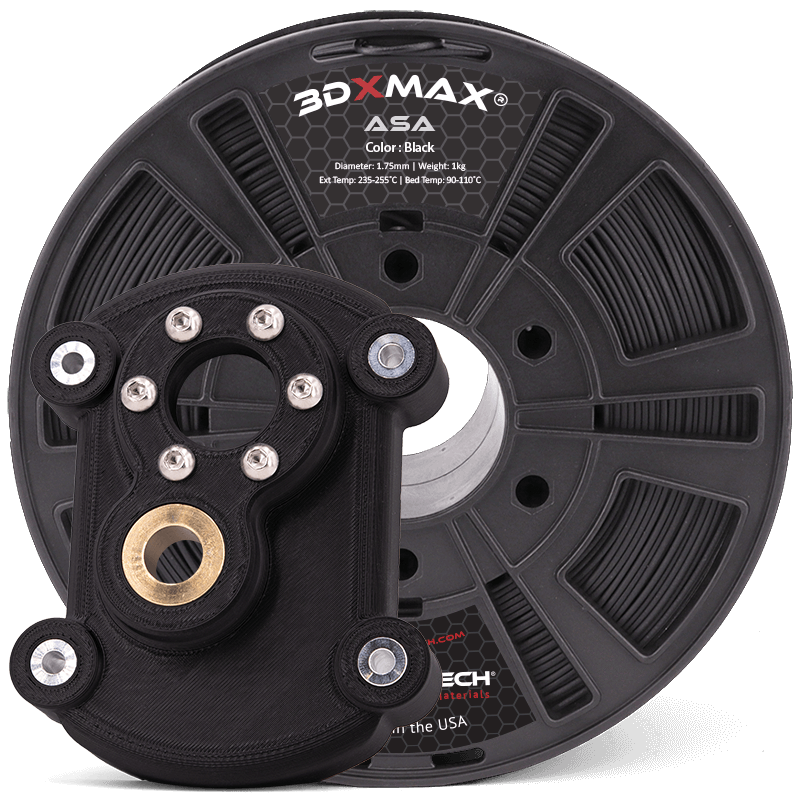

Carbon Fiber Filament

Carbon fiber 3D printing materials deliver exceptional strength, stiffness, and durability, making them ideal for high-performance applications in aerospace, defense, and automotive. In manufacturing, their lightweight and heat-resistant properties enable the production of robust tooling, fixtures, and end-use parts that stand up to demanding environments. These benefits also extend to industries like medical and oil and gas, where reliability and efficiency are critical.

Shop Now

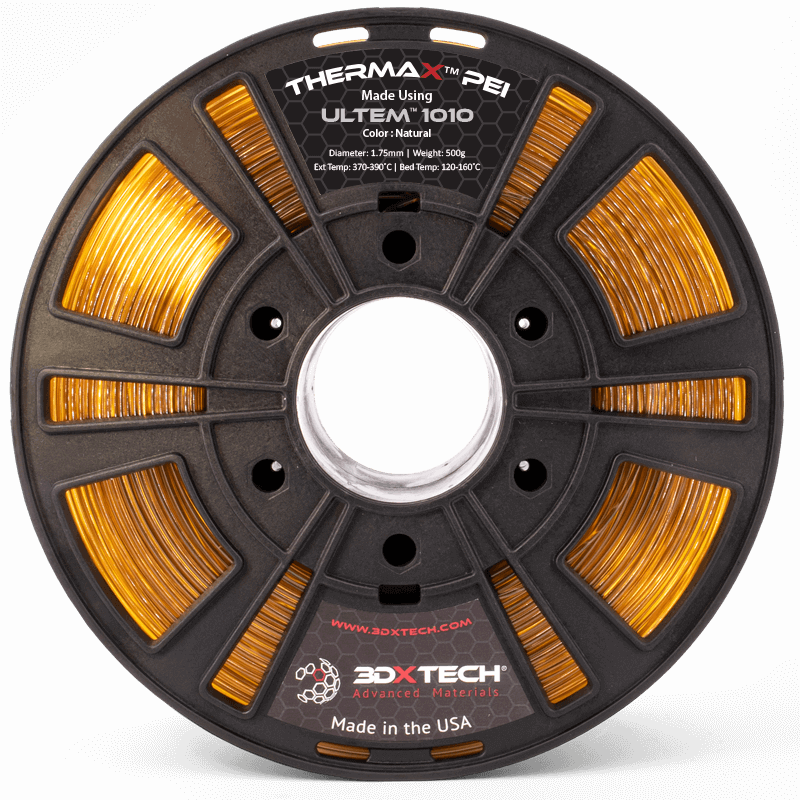

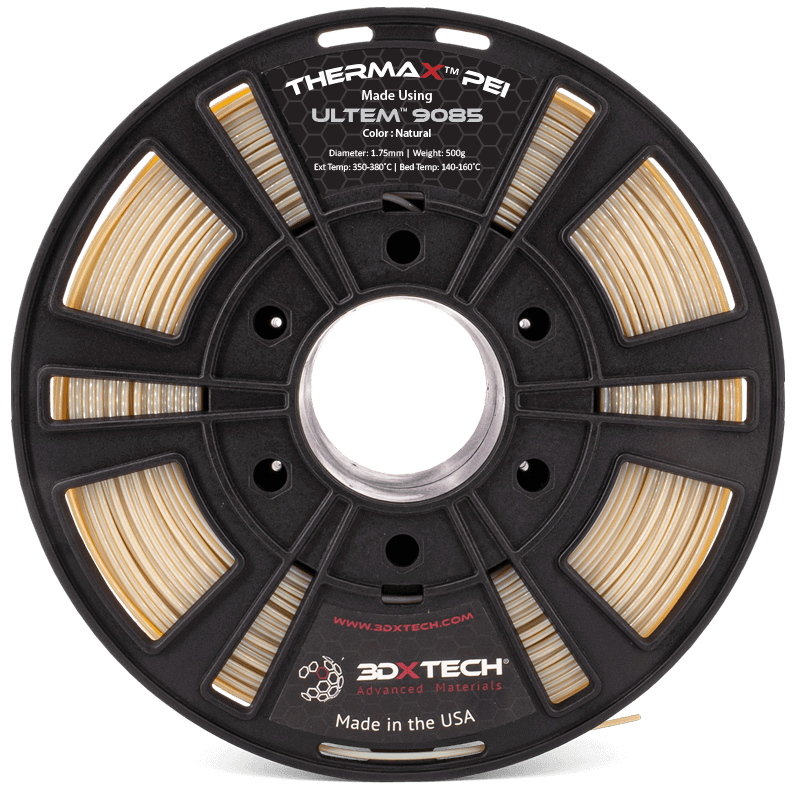

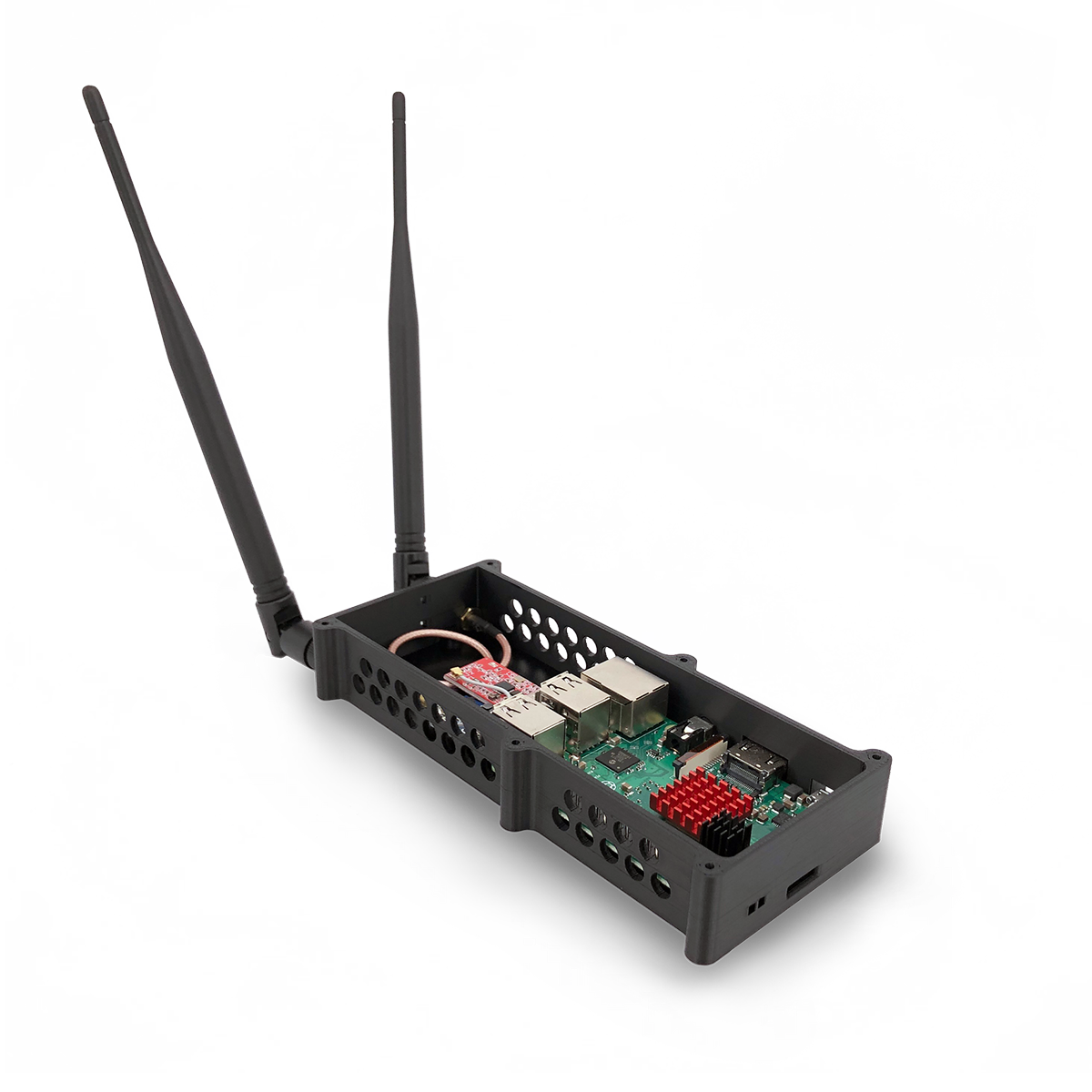

Ultra Performance Filaments

These are some of the strongest filaments available, designed for demanding manufacturing applications. With exceptional properties like high-temperature resistance, solvent resistance (both natural and synthetic), high dielectric strength, and excellent thermal conductivity, they ensure durability and performance in even the harshest production environments.

Shop Now