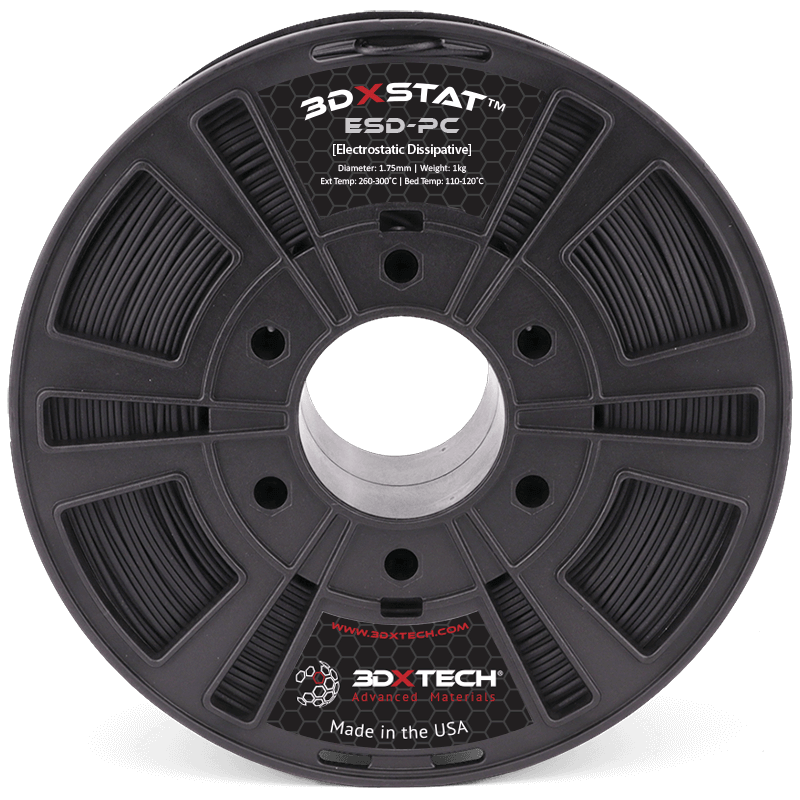

3DXSTAT ESD-PC

3DXSTAT ESD PC is an advanced ESD-Safe compound designed for use in critical applications which require electrostatic discharge (ESD) protection. Made using cutting-edge multi-wall carbon nanotube technology, state of the art compounding technology, and precision extrusion processes. Target surface resistance of 10^7 to 10^9 Ohm.

MADE IN THE USA

We manufacture all of our filaments in our 68,000 ft² manufacturing facility (located in Grand Rapids, Michigan) using state-of-the-art equipment and processes. Our goal continues to be to make the most innovative filaments on the market – targeting difficult end-use applications.

Print Recommendations

You May Also Like

Make sure you can get temps

Nozzle temp requirements exceeded my machine capabilities needing over 300C. Good material prints nice however layer separation common unless you print slow and hot. Very hard material and looks good.

Good for small stuff

It has been great for small prints, but on big prints it is very prone to warping and layer separation. Probably just a PC issue, and maybe I just haven't found the magic recipe yet.

Tough Stuff!

This filament seems fantastic! I'm having a few issues printing very large parts (30+cm x 30+cm), but that's my problem, not the filament. The smaller prints that I have done are amazing, and ridiculously tough! Like printing metal.

Pricey, but good

The prints I made with this were stiff and tough and generally high quality, which is what I was looking for from PC. The odor was indeed far less awful than other PC I've printed with, but I still print it in an enclosure (for heat and fumes). It does warp/lift a bit when using ABS slurry as an adhesive. Note that using slurry (acetone) on Kapton/PEI film will attack the kapton and cause bubbles under the film. I couldn't get it to stick to the kapton without the slurry, so slurry directly onto glass is probably the best option. PVA on glass might work too, but the required temps seem high for PVA. Running it a bit hotter (~292C 1st layer, 287C 2nd layer, 120C bed) and slower (40mm/s) did result in better print quality than the listed settings.

Easy to print and very stiff material

I use this material *** SST hex driver. I touch of glue stick on the PEI sheet is all that is needed for a success full print on the i3 mk2. The results look better at 295C, 40mm/s 15mm/s 1st layer. Bridging works a bit better at 275C